Before the expansion test of plate heat exchanger, it is necessary to determine whether the expansion tube can be operated correctly. Let's take a look at the specific expansion test operation process.

1. During the expansion test, all conditions (including the material, mechanical properties, dimensions, expansion tools, surrounding environment and operator of the tube and tubesheet of the plate heat exchanger) shall be consistent with the actual working conditions.

2. During the expansion test, the diameter of tube and tube sheet hole before and after expansion should be accurately measured to determine the expansion rate, and various signs on the outer surface of plate heat exchanger and the axial elongation of tube should be carefully observed.

3. After expansion, sealing test and tensile test should be carried out.

4. Remove the tube from the tube sheet and observe the deformation of the expanded part.

In the process of daily use, the equipment should be maintained and inspected regularly, so as to extend the service life of the equipment. During expansion test of plate heat exchanger, the protective measures should be taken, and the operation behavior should be standardized, so as to avoid the unknown danger in the process of expansion test.

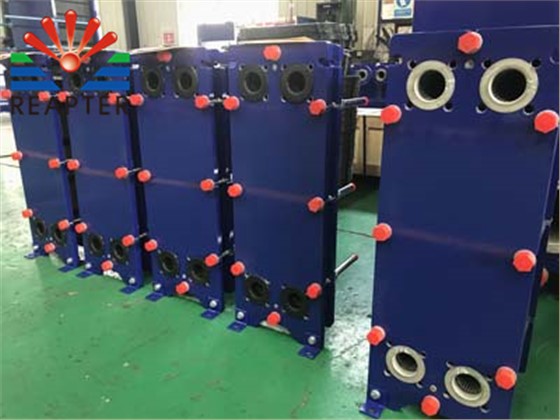

Qingdao Ruipute Heat Exchange Equipment Manufacturing Co., Ltd. is a new energy-saving high-tech enterprise specializing in R &D ,design, production and manufacturing, installation and commissioning, and technical services of high-efficiency and energy-saving heat exchangers. If you have the problem of expansion test of plate heat exchanger, you are welcomed to visit us for consultation.

Food grade plate heat exchanger

Food grade plate heat exchanger Plate And Shell Heat Exchanger

Plate And Shell Heat Exchanger