So how does a small heat exchange station in the community connect individual households in the community to the upstream heat exchange station?

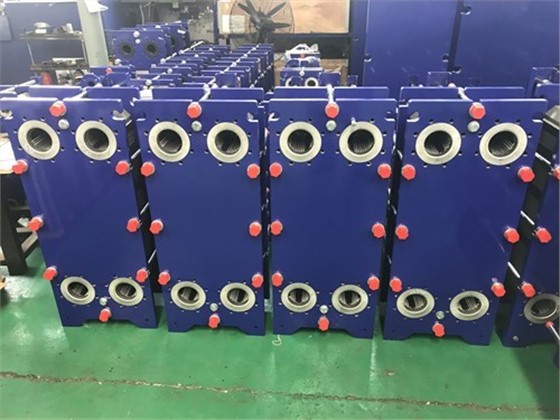

The answer is the plate heat exchanger.

This independent small house covers an area of more than ten square meters, and the larger one is twenty square meters. However, it provides winter heating for tens of thousands of families in the community and brings hot water to thousands of families because it has a plate heat exchanger for it.

Support, the plate heat exchanger has a small footprint, high heat exchange efficiency, and the operating cost and expense are at least 2/3 lower than the tube type.

With the development of waste heat recovery and environmental protection projects, attention has been paid to improving the quality of heat supply, and the direct supply station of the previous power plant has been converted to an intermediate supply station for centralized heating.

The district heat exchange station transmits the high-temperature steam produced by the thermal power plant to each residential district and transfers the heat of the steam to the district pipe network, like a transformer, converts the high-temperature steam into 70-80 degrees water for heating.

Demand for heating.

If you want to have a good heat exchange effect, you must first make a high heat exchange efficiency and more economical solution for the entire working condition. Engineers with 20 years of industry experience use Alfa Laval and GEA original factory selection software to select the model.

In contrast to common selection software, the original software package contains actual cases in various industries, which has a high reference significance for more economical and accurate selection.

Behind the export of the whole machine, plates, and rubber strips to foreign countries in 13 years is the company's persistent R&D spirit of "Honesty, Prosperity, and Innovation".

This is what Qingdao Ripute has always been doing. For the heating plate heat exchanger in winter, select Ripute.

Food grade plate heat exchanger

Food grade plate heat exchanger Plate And Shell Heat Exchanger

Plate And Shell Heat Exchanger