Now the application of plate heat exchanger has been very extensive, for the installation of plate heat exchanger, the use and maintenance of industry experienced engineers to summarize for you.

Installation

1? When lifting, please keep the equipment level to prevent the rope from slipping.

2? Before installation, please check whether the pipeline design is reasonable, whether it can be installed according to the label, and whether the diameter of the pipeline flange matches the interface of plate heat exchanger. If the diameter difference is too large, it will affect the exchange effect. The plate heat exchanger will be damaged.

Operation

1 Check that all connections are tight. Make sure that the system parameters do not exceed the working pressure and temperature values allowed on the manufacturing label. When the above conditions are met, the heat exchanger can be started.

2?Start the heat exchanger

Before starting the pump, open all valves and drain valves of the heat exchanger, then close the inlet valve of the heat exchanger. After starting the pump, slowly open the pump outlet valve to gradually increase the pressure. To prevent unidirectional overpressurization, open the inlet valves for both fluids entering the heat exchanger at the same time, or slowly fill the low-pressure side first, then the low-pressure side. Ground the fluid on the high pressure side. After emptying the heat exchanger of gas, close the bleed valve. If the plate heat exchanger has not been used for more than six months, the water pressure should be tested before use. Usually, clean water is used to test the pressure at 1.3 times the design pressure, and the heat and cold should be kept under pressure for 30 minutes without leakage before it is considered qualified.

3?Heat exchanger operation

The operating parameters may not be changed while the heat exchanger is operating. Do not exceed the maximum allowable values listed on the manufacturing label. To ensure proper temperature or pressure drop, make any adjustments to the fan slowly to avoid affecting the system.

4?When closing, close the high temperature and high pressure fluid valve first, then close the low temperature and low pressure fluid valve.

Equipment maintenance

After a period of operation, the plate heat exchanger (different media, different time) deposits on the surface of the plate due to particles in the fluid, increasing the thermal resistance and leading to a decrease in heat transfer efficiency, which should be regularly maintained by the maintenance staff according to the operating conditions. If the fluid is more prone to fouling, a corresponding cleaning system should be installed on the piping during installation. At the end of the job, drain the original fluid from the machine and then turn on the cleaning system to clean it. This can effectively extend the normal use time of the plate heat exchanger.

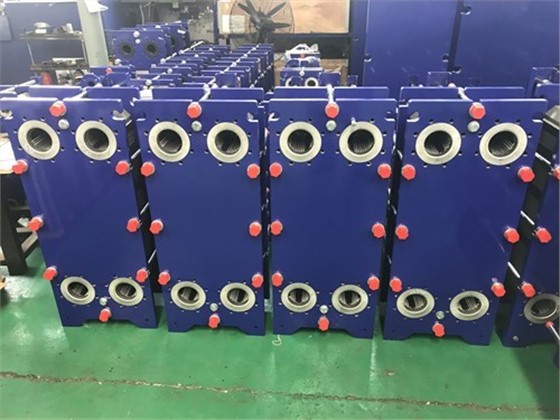

Reapter Ltd. is engaged in energy-saving heat exchanger R & D design, manufacturing, installation and commissioning, technical services in a four-in-one new energy-saving high-tech enterprises. We produce fully welded shell heat exchanger, half welded plate heat exchanger, plate heat exchanger, wide channel heat exchanger and related process and control system, heat exchanger plate, heat exchanger gasket and replacement heat fittings, welcome to call us.

Food grade plate heat exchanger

Food grade plate heat exchanger Plate And Shell Heat Exchanger

Plate And Shell Heat Exchanger