First, the plate design to avoid dead ends: the plate corrugated area and the inflow area should be set up reasonably, in use to ensure that the media in the flow channel area are effective flow channel, to avoid stagnant areas. This can not only improve the heat transfer effect of the plate, maximize the heat transfer capacity of the plate, and can be easy to clean online when shutdown, to achieve the use of health level requirements.

Second, to avoid internal leakage: usually in the rubber strip is designed with two seals, in the two sealing area designed with a drainage groove, to avoid the occurrence of internal leakage caused by the rubber strip. But the plate heat exchanger plate perforation and other internal leakage, it is difficult to be found, because most of the plate material is austenitic stainless steel, highly susceptible to pitting, pitting at the beginning of the leak is very small, and so on through the composition of the detection occurs, a large number of pollution events may have occurred, the use of conventional heat transfer equipment on the working conditions may not be a problem, but in the pharmaceutical industry is a big deal, so the use of pharmaceutical industry-specific Double-walled plate heat exchanger to avoid internal leakage is the pharmaceutical industry must do things.

Qingdao Reapter developed a special double-walled plate heat exchanger for the pharmaceutical industry, two thin stainless steel plate synchronous pressing, using laser welding, the impact on heat transfer is not large, when one of the plates perforated, will turn internal leakage into external leakage, refuse to leak inside, to ensure the quality of the medium, to remove the internal leakage for you, rest assured that the use of double-walled plate, welcome to call for advice.

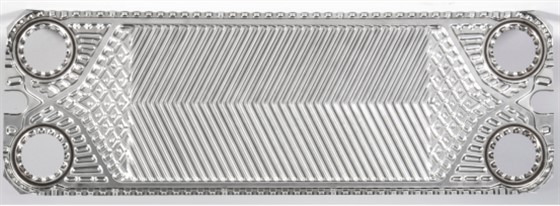

Food grade plate heat exchanger

Food grade plate heat exchanger Plate And Shell Heat Exchanger

Plate And Shell Heat Exchanger