Some time ago, Ripter’s customers said that a part of their production process is to cool down the Chinese medicine particles added with water. The particle size of the Chinese medicine is about 60 meshes. Whether there is a problem of clogging when changing plates.

An engineer with 20 years of industry experience from RPT answered that there is certainly no problem with using a plate heat exchanger. First of all, the size of the particles is 60 mesh, which is about 0.42mm, but the particles are mixed with water and formed

This reduces energy consumption and directly reduces the cost of electricity and heat input.

Secondly, in terms of the maintenance and service cycle of heat exchange equipment, the disassembly of the tube type is more difficult than the plate type, and it is easy to adhere to the inner wall for a long time, even if the particles are small, it will affect the passage.

It is also because the tubular heat exchanger previously used by the customer has some of the above problems, mainly due to the high operating cost. Therefore, the upgrade and optimization of the production line thought of using a plate heat exchanger instead of the tubular heat exchanger.

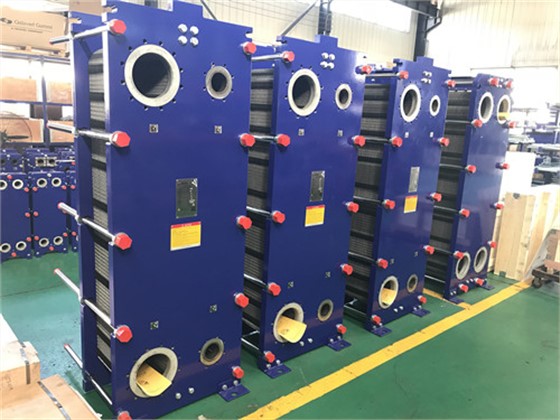

The model design drawings and the customer cases we have made before are explained with the customers. The customers relieved their suspicion. After visiting the factory, they expressed their desire to reach a cooperative relationship with RPT and upgrade their pharmaceutical production lines together.

.

In fact, the times are changing, people’s thinking is also changing, and Ripter’s technology is also changing. In various application scenarios, plate heat exchangers replaced tube and spiral plate heat exchangers with more heat exchanger types.

, Also has a good reputation and customer cases in Haier, Sinopec, PetroChina and other companies in different industries at home and abroad, as well as customized services.

Food grade plate heat exchanger

Food grade plate heat exchanger Plate And Shell Heat Exchanger

Plate And Shell Heat Exchanger