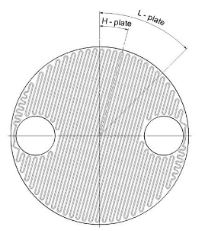

The plate and shell heat exchangers produced by Qingdao Reapter Heat Exchange Equipment Manufacturing Co., Ltd. have a variety of specifications, and the plate corrugation pattern is also different, which means that the plates have different corrugation angles and pressing depths.

Changing the corrugation angle can form flow channels with different efficiencies and pressure drops. When combined into a heat exchanger, it is designed to achieve the best combination of plate layouts.

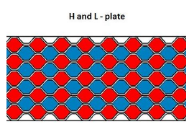

H-type plate has good heat transfer effect and large resistance.

The L-shaped plate has low resistance and the heat transfer effect is not as good as the H-shaped plate.

The M combination can perfectly match heat transfer and resistance loss.

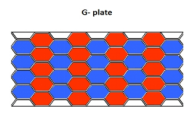

G-type (deep corrugated) plates are suitable for gas / gas-exchange, medium particle size and viscosity conditions. It has a larger flow channel cross-sectional area.

Qingdao Reapter Heat Exchange Equipment Manufacturing Co., Ltd. can provide design and manufacture of plate and shell heat exchangers according to different usage conditions and media of customers. It has been exported to Europe and the United States for more than ten years, with zero quality complaints.

Contact info

Joey Wong

joey@reapter-phe.com

WhatsApp/phone:86-15662770315

Food grade plate heat exchanger

Food grade plate heat exchanger Plate And Shell Heat Exchanger

Plate And Shell Heat Exchanger