Friends familiar with Alfa Laval products should know that the common hanging holes of Alfa Laval are as follows: round and swallow tail. What's the difference between the hanging holes on the plate of plate heat exchanger, and what scenarios are these two applied to?

Knowledgeable friends should be able to say that round hanging hole is generally small plate type, swallow tail type is large plate type.

Yes, that's right. Alfa Laval M3 to M10 series are all round hanging holes. The diameter of the corner hole is not more than 100 mm, while the diameter of the corner hole is more than 100 mm. For example, the small 105mm tl10p, the medium 140mm M15, and the large 230mm mx25 are all swallow tail type.

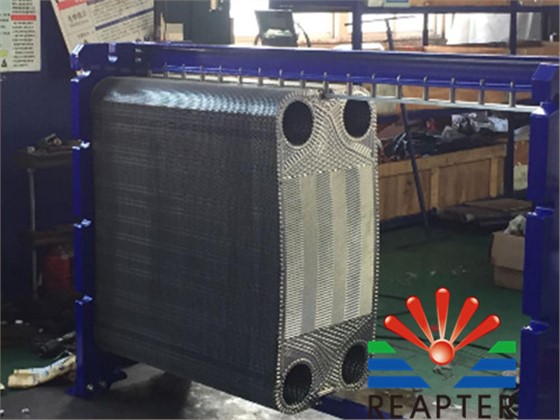

The logic is very easy to understand. The guide rod of the circular hanging hole is also round, while the swallow tail type and the lead screw are I-shaped, as shown in the figure

When installing, the round hanging hole can be directly installed, while the dovetail type needs to be hung.

And this kind of situation, isn't it strange that there are different hanging holes on the plate of plate heat exchanger. Why do the plates that have been drilled and formed need to be processed again in the hanging hole? Why are some other swallow tail models processed or not processed?

Generally, this kind of situation will only appear in a large version, which is used for reinforcement. Although the design pressure is about 25bar, the larger the version, the greater the flow rate, the higher the flow rate, and the higher the actual pressure.

Therefore, in order to ensure the stability of product operation, these details should be done in place. To sum up, the hanging holes on the plate of plate heat exchanger are different, which also have an impact on heat exchange

Food grade plate heat exchanger

Food grade plate heat exchanger Plate And Shell Heat Exchanger

Plate And Shell Heat Exchanger