In industry, the utilization rate of NH3/CO2 cascade refrigeration system has become higher and higher, because based on environmental considerations, long-term use of a large amount of toxic medium NH3 is not a long-term solution after all, and in some food industries, considering the personal

Safety and food safety, there are explicit restrictions on the use of NH3, so the current use of NH3/CO2 cascade refrigeration system is currently the most promising low-temperature refrigeration solution.

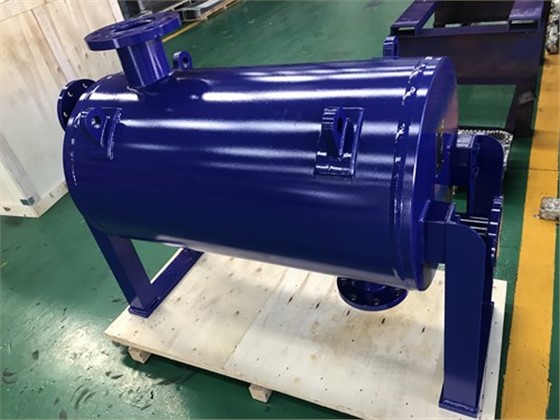

However, this kind of system generally has high working pressure, higher requirements on parts and equipment, and also has low temperature limitations. The general plate heat exchanger cannot be used on it, so the shell-and-tube heat exchanger is generally used.

.

However, shell and tube heat exchangers occupies a large area and have low heat exchange efficiency. Therefore, some large-scale cold storages that pay attention to efficiency often choose plate and shell heat exchangers.

As far as the factory is concerned, -80? is completely no problem, plus 100bar withstand voltage.

(Generally, the plate heat exchanger is 25bar)

Seeing this, do you have a deeper understanding of plate and shell heat exchangers?

As a niche product, its use is not so popular, but as a new thing, its future is full of infinite possibilities.

Food grade plate heat exchanger

Food grade plate heat exchanger Plate And Shell Heat Exchanger

Plate And Shell Heat Exchanger