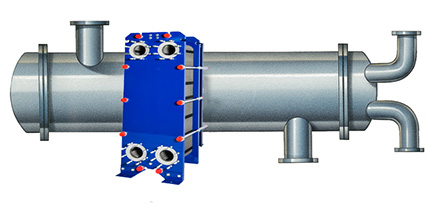

Product introduction

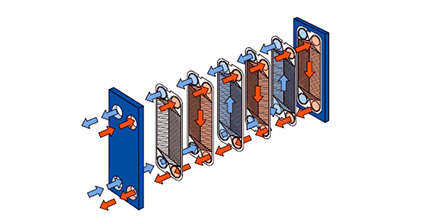

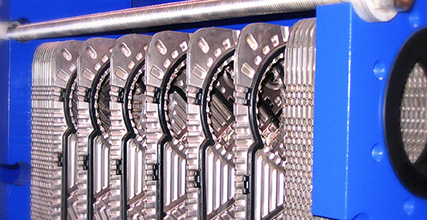

The plate condenser consists of plates that are welded together in pairs to form a so-called plate set. The concept of a plate set leads to two different types of channels: a weld channel for condensing steam and a gasket seal channel for cooling water. This type of plate is specially designed for optimum condensation. It has an asymmetrical arrangement with a large gap on the steam side and a small gap on the cooling water side. This makes it possible to maintain a very low pressure drop at the steam end while maintaining a certain speed and turbulence on the cooling water side. This maximizes heat transfer efficiency and minimizes fouling.

Plate condensers are specially developed for condensing steam under low pressure or vacuum conditions in evaporation and distillation systems. It can meet a variety of specific applications and capabilities requirements. The steam inlet fitting is large and the two condensate outlets are small. The cooling water fitting is a medium size and is located in the center of the plate.

Features

-

-

Lower cost

Lower cost

Due to the high heat transfer efficiency, this means less heat exchange area and higher cost efficiency than conventional shell and tube type, especially when stainless steel or titanium is required. The compact design also saves space, thus reducing transportation and installation costs.

-

-

Less fouling

Less fouling

Due to the high strength turbulence created by the specially designed corrugated sheets, there is less fouling on the cooling water side than the shell and tube condenser.

-

-

Easy to clean

Easy to clean

The cooling water side is easy to clean, whether in the way of mechanical or chemical.

-

-

Easy to expand

Easy to expand

Just add an extra "plate group" in the existing frame.

-

-

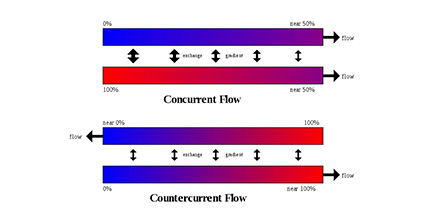

Complete counterflow

Complete counterflow

A greater degree of subcooling of non-condensable gases can be achieved compared to shell and tube equipment. Therefore, the load of the vacuum pump will be reduced.

Range of application

Alumina, food industry, sugar industry, beverage industry, industrial wastewater, etc.