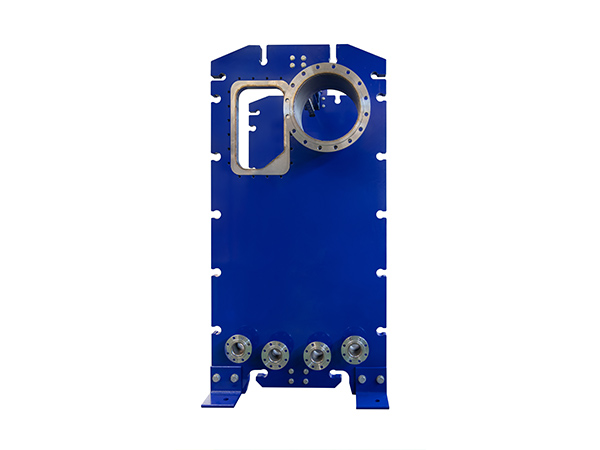

The first semi welded titanium type plate evaporator in China

In the process of seawater cooling, refined salt production, chlor-alkali chemical industry, ocean-going marine cooling, seawater desalination, special materials are needed. Titanium has stable chemical properties, such like good high temperature resistance, low temperature resistance, strong acid resistance and strong alkali resistance, as well as high strength and low density, so it’s used to make titanium type plate heat exchangers.

Titanium and titanium alloys have low specific gravity, high strength and high and low temperature properties. They have excellent resistance in wet chlorine, most acid, alkali and salt media such as oxoacid, urea, nitric acid, tartaric acid and carbolic acid. Cracking performance and corrosion resistance make it a new type of structural material with a wide range of prospects. It is widely used in petrochemical, military, aerospace, pharmaceutical and other fields.

However, due to its high chemical activity, high melting point, low heat flux and poor thermal conductivity under high temperature, titanium has good weldability that is different from carbon steel, ordinary low alloy steel, stainless steel, aluminum and copper. Therefore, the welding process for titanium is extremely demanding, and almost no manufacturer in China has the ability to produce a semi-welded plate evaporator.

And we saw the broad prospect of titanium in the application of heat exchangers. After years of process adjustment and technical update, and the unremitting efforts of the scientific research team, we have recently produced the semi welded titanium type plate evaporator in China, this it also fills the market gap of plate heat exchangers, providing a new impetus for the development and application of plate heat exchangers.

The semi welded type titanium plate heat exchanger has been successfully developed and produced, which greatly improves the heat exchange efficiency. As the required heat exchange area is greatly reduced, the input cost is greatly reduced, and the direct economic benefits are obvious. Moreover, due to its compact structure, small footprint, difficulty in scaling, easy cleaning and maintenance, the semi welded type d plate evaporator will be in widely use.

REAPTER is a heat exchanger manufacture in China, We have 50 production technicians and 400 sets of heat exchanger production mold , we are professional in development, manufacture and service of Plate & gasket for heat exchanger, plate heat exchanger.

Related information

- Correct installation process of plate and shell heat exchanger

- Do you really understand the types and varieties of plate heat exchangers?

- Plate and shell heat exchangers for low-pressure steam heat recovery are the most environmentally-friendly artifacts that have been in use recently.

- Detachable plate heat exchanger plate corrosion and gasket aging causes, everything you want to know is here

- As for the price of plate heat exchanger, you should consider these factors

- Development and application of plate and shell heat exchangers in China

Relevant article

- Heat station supporting plate heat exchanger installation is a technical work, these points should be noted

- Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what

- Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency

- A high-quality petrochemical plate heat exchanger in the production of what to consider

- These causes of chemical plate heat exchanger gasket aging you may not know

- Chemical plant plate heat exchanger, sulfuric acid cooling needs attention

- High-end plate heat exchanger customization, specifically for your special working conditions

- The working principle of gasket type industrial plate heat exchanger and the scenarios of its use are worth knowing in depth

- Still worrying about the wholesale price of industrial plate heat exchangers? An article to make you no longer tangled

- The original lubricant in the chemical plate heat exchanger plays so many roles!

Latest information

- Heat station supporting plate heat exchanger installation is a technical work, these points should be noted

- Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what

- Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency

- A high-quality petrochemical plate heat exchanger in the production of what to consider

- These causes of chemical plate heat exchanger gasket aging you may not know

- Chemical plant plate heat exchanger, sulfuric acid cooling needs attention

- High-end plate heat exchanger customization, specifically for your special working conditions

- The working principle of gasket type industrial plate heat exchanger and the scenarios of its use are worth knowing in depth

- Still worrying about the wholesale price of industrial plate heat exchangers? An article to make you no longer tangled

- The original lubricant in the chemical plate heat exchanger plays so many roles!