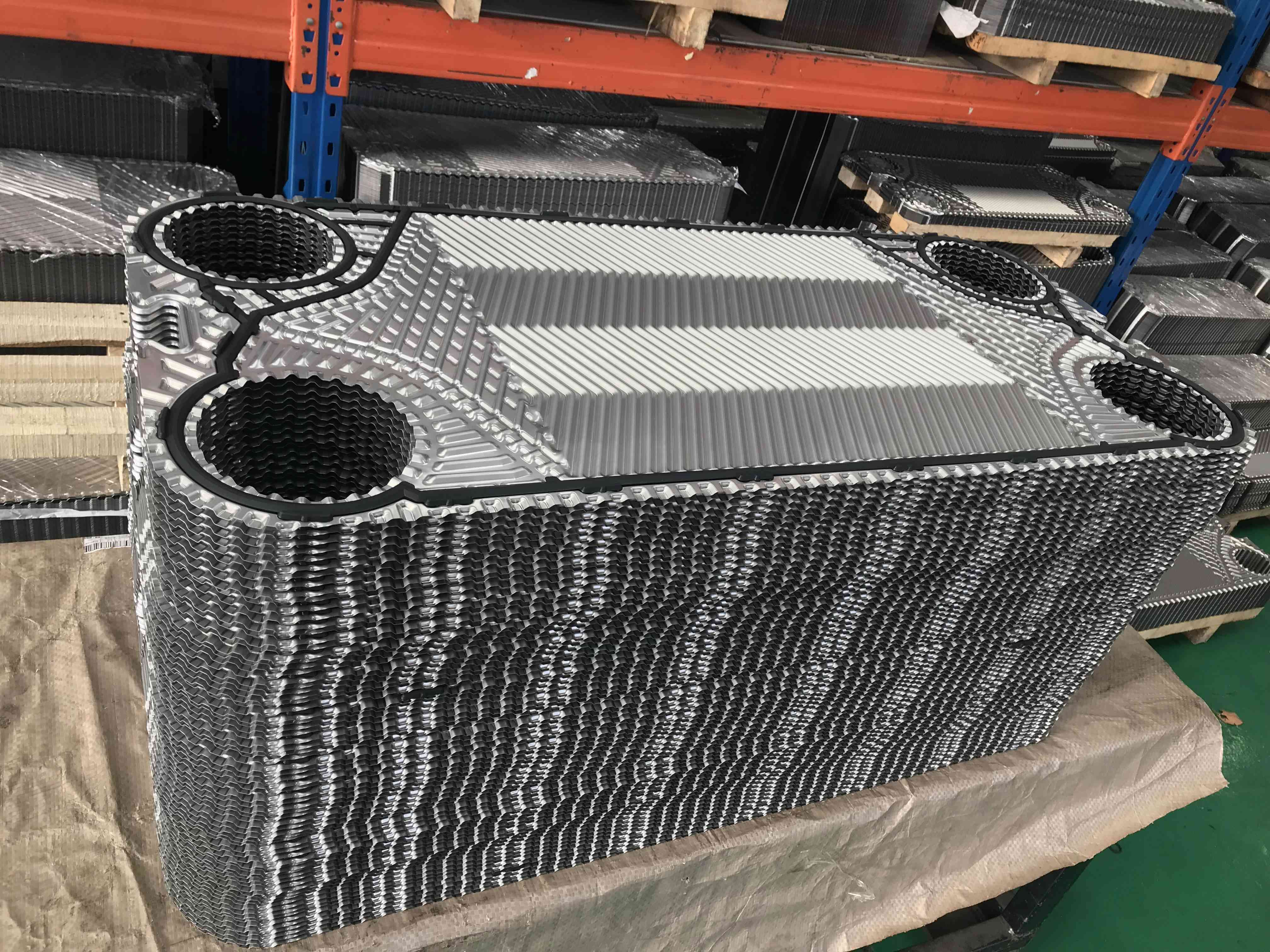

Ruipute Quality Manufacturing-Plates of plate Heat Exchanger

Qingdao Ruipute has been committed to the application innovation and development the plates of plate heat exchanger with its strong strength and innovative spirit. The forefront of the development of the device industry.

The plates of the company's plate heat exchangers are all formed by the most advanced automated giant press and high-precision molds. The advantages are:

l The corrugation depth is the same on the same plate, so as to ensure the perfect connection of each contact point;

l The pressure bearing capacity of the plate is enhanced to avoid thermal stress fatigue and mechanical fatigue corrosion caused by vibration and high-frequency tremor;

l There is no excessive stamping area on the plate, and no hidden cracks (cracks that can be found under the microscope) will be generated;

l The plate has better mechanical properties, avoiding leakage caused by hidden cracks.

l The height of the metal lines on the plate is uniform; the contact points are evenly distributed. When the medium flows through the plate, the turbulence is strengthened to maximize the heat transfer efficiency.

l The thinnest plate can be up to 0.4mm; reduce the weight of the equipment and obtain a higher heat transfer coefficient under the requirement of ensuring the pressure.

l The plate has soft and hard plates, some special plate types, there are two different angles of corrugation on the same plate, and a variety of flow channel combinations can be obtained;

l The plate has various groove depth specifications such as shallow groove, deep groove and super deep groove. The depth of the corrugated groove is 2 ~ 12mm, which can meet the requirements of various working conditions;

l According to the different requirements of customers, there are unilateral flow and multi-flow side;

l Due to the high density of the mold, our company has a full range of plate materials. In addition to ordinary austenitic stainless steel, it can also press 254SMo dual-phase steel, Ti, Ni, aluminum-magnesium alloy, C276, G30 and other materials. It can press plates with thickness range of 0.4-1.3mm.

l The plates of our company are all pressed at one time. Before the plates are pressed, the volatile oil and the surface coating of the plates are applied. This can effectively protect the mold, at the same time enhance the ductility of the plates, and greatly reduce the cracks caused by hydraulic stretching....

The reasonable guide area setting of the plates of plate heat exchanger, even if the length and width of the plates are relatively small, can make the fluid fully evenly distributed in each position of the plates, so that all the heat exchange areas participate in efficient heat exchange, and no heat exchange death Zone, there is no flow dead angle, and chloride corrosion caused by fouling is not easy to occur; the pressure loss in the split area is minimized, the allowable pressure drop can be fully utilized, the flow rate of the convection heat exchange part is increased, and the overall heat exchange efficiency is improved.

Related information

- Schematic diagram of internal structure of plate and shell heat exchanger

- How to choose the right heat exchanger plate, Qingdao Reapter give you detailed answers

- About plate sterilizer plate heat exchanger, how much do you know

- What is a mold removal block? How to buy the manufacturer after the mold removed the block produced plate accessories?

- Multi-process combination of plate and shell heat exchanger

- How can you use the Alfa Laval plate heat exchanger for less money in the brewing process

Relevant article

- Heat station supporting plate heat exchanger installation is a technical work, these points should be noted

- Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what

- Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency

- A high-quality petrochemical plate heat exchanger in the production of what to consider

- These causes of chemical plate heat exchanger gasket aging you may not know

- Chemical plant plate heat exchanger, sulfuric acid cooling needs attention

- High-end plate heat exchanger customization, specifically for your special working conditions

- The working principle of gasket type industrial plate heat exchanger and the scenarios of its use are worth knowing in depth

- Still worrying about the wholesale price of industrial plate heat exchangers? An article to make you no longer tangled

- The original lubricant in the chemical plate heat exchanger plays so many roles!

Latest information

- Heat station supporting plate heat exchanger installation is a technical work, these points should be noted

- Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what

- Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency

- A high-quality petrochemical plate heat exchanger in the production of what to consider

- These causes of chemical plate heat exchanger gasket aging you may not know

- Chemical plant plate heat exchanger, sulfuric acid cooling needs attention

- High-end plate heat exchanger customization, specifically for your special working conditions

- The working principle of gasket type industrial plate heat exchanger and the scenarios of its use are worth knowing in depth

- Still worrying about the wholesale price of industrial plate heat exchangers? An article to make you no longer tangled

- The original lubricant in the chemical plate heat exchanger plays so many roles!