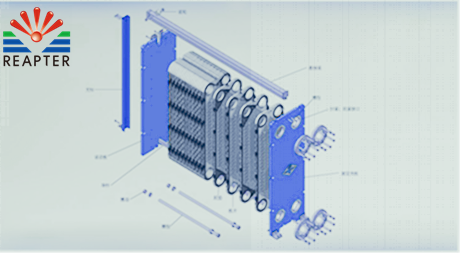

Operating parameters of plate heat exchanger

Today, the plate heat exchanger manufacturer will introduce you to the relevant information about the operating parameters of the plate heat exchanger. I hope that everyone will be helpful to you after reading it, and let friends who want to know more about it. Let's get to know it together.

1. The working pressure is below 2.5MPa, the plate heat exchanger is sealed by gaskets, the periphery of the seal is very long, and the support condition of the two seals of the corner holes is poor, and the gasket cannot obtain satisfactory compression force. Therefore, the maximum working pressure of the plate heat exchanger at that time is only 2.5MPa; when the veneer area is more than 1m2, the working pressure is often lower than 2.5MPa;

2. The working temperature is below 250?. The working temperature of the plate heat exchanger is determined by the temperature that the gasket can accept. When using rubber elastic gaskets, the maximum working temperature is below 200?; when using compressed asbestos wool gaskets, the maximum working temperature is 250~260?;

3. Refer to the parameters of the plate heat exchanger, it is not suitable for the heat exchange of the medium that is easy to block the channel. The passage between the plates of the plate heat exchanger is very narrow, usually 3~5mm. When the heat exchange medium contains larger solid particles or fibrous substances, it is easy to block the passage between the plates. For this kind of heat exchange occasions, we should consider importing equipment filtering equipment, or choose a regenerative cooling system.

Operating parameters are very important to plate heat exchangers. We only have to remember the operating parameters of plate heat exchangers at all times and pay more attention to its various parameters during use to ensure the normal operation of the machine.

Related information

- Customized processing of wide gap plate heat exchanger

- After consulting the master for ten years, only to know that the plate and shell heat exchanger applications are so many!

- The repairer will never tell you that replacing Qingdao plate heat exchangers is much easier than cleaning

- Qingdao Deman Beer Technology Equipment Co., Ltd. uses Ripute steam heating heat exchanger case

- Corrugation, strength and stiffness of plate heat exchanger plates

- How to choose the right plate and shell heat exchanger for your application?

Relevant article

- Heat station supporting plate heat exchanger installation is a technical work, these points should be noted

- Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what

- Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency

- A high-quality petrochemical plate heat exchanger in the production of what to consider

- These causes of chemical plate heat exchanger gasket aging you may not know

- Chemical plant plate heat exchanger, sulfuric acid cooling needs attention

- High-end plate heat exchanger customization, specifically for your special working conditions

- The working principle of gasket type industrial plate heat exchanger and the scenarios of its use are worth knowing in depth

- Still worrying about the wholesale price of industrial plate heat exchangers? An article to make you no longer tangled

- The original lubricant in the chemical plate heat exchanger plays so many roles!

Latest information

- Heat station supporting plate heat exchanger installation is a technical work, these points should be noted

- Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what

- Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency

- A high-quality petrochemical plate heat exchanger in the production of what to consider

- These causes of chemical plate heat exchanger gasket aging you may not know

- Chemical plant plate heat exchanger, sulfuric acid cooling needs attention

- High-end plate heat exchanger customization, specifically for your special working conditions

- The working principle of gasket type industrial plate heat exchanger and the scenarios of its use are worth knowing in depth

- Still worrying about the wholesale price of industrial plate heat exchangers? An article to make you no longer tangled

- The original lubricant in the chemical plate heat exchanger plays so many roles!