The conditions of using expansion joint of plate heat exchanger

The expansion joint of plate heat exchanger plays the role of deformation compensation in the use of equipment, but not all equipment need to set expansion joint, so under which conditions should expansion joint be set?

1. In the design of fixed plate heat exchanger, if the equipment operates under low temperature differential stress, expansion joint of plate heat exchanger is generally not considered; if the temperature difference between shell and heat exchange tube is large, expansion joint should be considered. The concrete basis is the shell axial stress, the heat exchange tube axial stress and the connection pull-out force between the heat exchange tube and the tube sheet. If one of them can not meet the strength condition, the expansion joint must be set.

2. In fixed plate heat exchanger, due to the temperature difference between shell side fluid and tube side fluid, the temperature changes of shell and tube bundle in working state and non working state are inconsistent, resulting in different thermal deformation of shell and tube bundle in working state. The shell and the tube bundle are fixed together by the tube sheet with high rigidity, which will inevitably cause the deformation of the shell and the tube bundle constrained each other in the working state, resulting in the axial load. In order to avoid shell damage, tube instability and tube pulling off from tube sheet, it is necessary to set a good deformation compensation element expansion joint in shell to reduce the axial load of shell and tube bundle.

The use of expansion joint under the above conditions can enhance the stability of the equipment and reduce the frequency of failure. Because the equipment contains different components of liquid, so the expansion joint is usually made of corrosion-resistant materials.

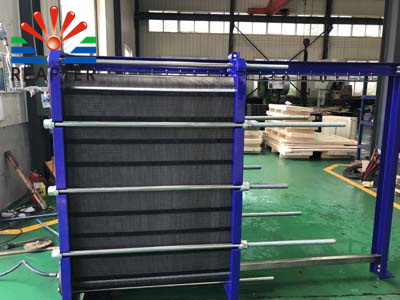

Qingdao Ruipute Heat Exchange Equipment Manufacturing Co., Ltd. is a new energy-saving high-tech enterprise specializing in R &D ,design, production and manufacturing, installation and commissioning, and technical services of high-efficiency and energy-saving heat exchangers. If you have the problem of expansion joint of plate heat exchanger, you are welcomed to visit us for consultation.

Related information

- Insiders tell you how to select and replace the gaskets of plate heat exchangers

- Qingdao Ruipute offers a perfect solution to the Alfa Laval plate heat exchanger for HVAC

- France will close the country again. Under the impact of the epidemic on imports and exports, where can I find imported quality plate heat exchangers?

- Qingdao Ruipute heat exchanger manufacturer introduced plate heat exchanger how to test pressure

- Causes of swelling of plate heat exchanger gaskets

- Everything you want to know about the GEA NT series plate heat exchangers is here

Relevant article

- Heat station supporting plate heat exchanger installation is a technical work, these points should be noted

- Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what

- Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency

- A high-quality petrochemical plate heat exchanger in the production of what to consider

- These causes of chemical plate heat exchanger gasket aging you may not know

- Chemical plant plate heat exchanger, sulfuric acid cooling needs attention

- High-end plate heat exchanger customization, specifically for your special working conditions

- The working principle of gasket type industrial plate heat exchanger and the scenarios of its use are worth knowing in depth

- Still worrying about the wholesale price of industrial plate heat exchangers? An article to make you no longer tangled

- The original lubricant in the chemical plate heat exchanger plays so many roles!

Latest information

- Heat station supporting plate heat exchanger installation is a technical work, these points should be noted

- Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what

- Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency

- A high-quality petrochemical plate heat exchanger in the production of what to consider

- These causes of chemical plate heat exchanger gasket aging you may not know

- Chemical plant plate heat exchanger, sulfuric acid cooling needs attention

- High-end plate heat exchanger customization, specifically for your special working conditions

- The working principle of gasket type industrial plate heat exchanger and the scenarios of its use are worth knowing in depth

- Still worrying about the wholesale price of industrial plate heat exchangers? An article to make you no longer tangled

- The original lubricant in the chemical plate heat exchanger plays so many roles!