Automatic welding of plate and shell heat exchangers

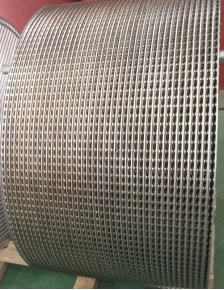

Plate and shell heat exchanger as the core heat transfer components, its production assembly and welding is a very important process. The plate pack welding quality directly affects the efficiency of heat transfer level.

Since then, the board beam of automated welding type foreign technology only mastered, can be said to have reached the point of monopoly, if you can achieve automatic welding assembly of the board beam, bring the significance of it will be unprecedented.

Since then, the board beam of automated welding type foreign technology only mastered, can be said to have reached the point of monopoly, if you can achieve automatic welding assembly of the board beam, bring the significance of it will be unprecedented.

If the realization of automated welding harness, then you can replace the manual operation, which will bring about a significant increase in production efficiency. The production time for a plate and shell heat exchanger will be reduced, and the economic cost will be reduced. In addition, it will change the previous instability of manual welding, improve the failure rate and heat transfer efficiency.

The automatic welding of the plate and shell heat exchanger packs was first developed by a large Chinese manufacturer, and then by Qingdao Ruipute. Ltd. has also realized this technology through continuous technological development and upgrading. After making full use of this technology, our production efficiency is improved and the production of complete equipment is also moving towards scale.

Related information

- Titanium plate heat exchanger manufacturers to explain product features

- It's because of gasket that making your heat exchanger breakdown

- The credit of "turning waste into treasure" must be credited to the plate heat exchanger

- The material selection of mariculture plate heat exchanger is very important

- Analysis of the material and application scope of the most complete plate heat exchanger gasket in history

- Small plate heat exchanger for home use, you deserve it!

Relevant article

- Heat station supporting plate heat exchanger installation is a technical work, these points should be noted

- Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what

- Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency

- A high-quality petrochemical plate heat exchanger in the production of what to consider

- These causes of chemical plate heat exchanger gasket aging you may not know

- Chemical plant plate heat exchanger, sulfuric acid cooling needs attention

- High-end plate heat exchanger customization, specifically for your special working conditions

- The working principle of gasket type industrial plate heat exchanger and the scenarios of its use are worth knowing in depth

- Still worrying about the wholesale price of industrial plate heat exchangers? An article to make you no longer tangled

- The original lubricant in the chemical plate heat exchanger plays so many roles!

Latest information

- Heat station supporting plate heat exchanger installation is a technical work, these points should be noted

- Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what

- Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency

- A high-quality petrochemical plate heat exchanger in the production of what to consider

- These causes of chemical plate heat exchanger gasket aging you may not know

- Chemical plant plate heat exchanger, sulfuric acid cooling needs attention

- High-end plate heat exchanger customization, specifically for your special working conditions

- The working principle of gasket type industrial plate heat exchanger and the scenarios of its use are worth knowing in depth

- Still worrying about the wholesale price of industrial plate heat exchangers? An article to make you no longer tangled

- The original lubricant in the chemical plate heat exchanger plays so many roles!