The pressure difference on both sides of the plate heat exchanger for seawater desalination is caused by these reasons

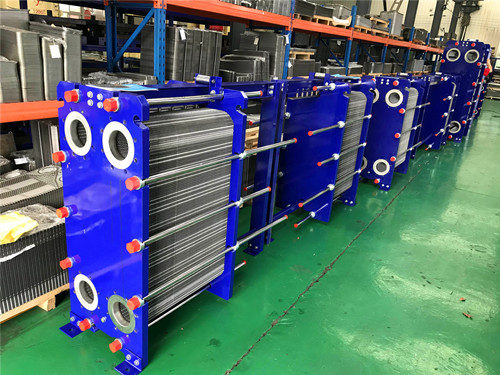

Plate heat exchangers have the advantages of small footprint and are widely used in various industries. At present, plate heat exchangers have also been widely used in the seawater desalination process and cooling water system of power plants, and have achieved excellent results.

Why do these factors appear when the equipment is in operation?

1. The equipment is blocked.

When the sediment content in the seawater is high, the pipeline is not completely purged after installation, or foreign matter enters the pipeline, the equipment flow channel is blocked, which reduces the cross-sectional area of the flow channel and increases the pressure drop value of the equipment.

2. There is a problem with the measuring instrument.

When there is a problem with the measuring instrument, the measured value will be deviated, resulting in a measurement error in the pressure difference

3. Affected by differences in physical parameters.

The temperature of the medium will affect the viscosity of the medium.

When the temperature of the medium decreases, its viscosity will increase, and the pressure drop will increase at the same flow rate.

4. The cross-sectional area of the runner changes.

The cross-sectional area of the flow channel of the plate is related to the corrugation depth, corrugation pitch and plate width.

The larger the cross-sectional area of the flow channel, the smaller the fluid velocity, the smaller the fluid resistance, and the smaller the pressure difference.

5. The size deviation of the plate corner hole.

When there is a deviation in the size of the corner hole of the plate, the flow resistance will change, and the pressure drop of the corner hole will deviate from the design value.

Therefore, whether it is a design problem or a use problem, all aspects of improperity will lead to pressure difference problems. In order to avoid such problems, not only should the installation and use, reasonable arrangement, but also ensure the accuracy during manufacturing to avoid these problems.

problem.

Qingdao RPT has rich design and manufacturing experience, reliable quality and high quality, and welcomes your consultation.

【Paper label】:seawater plate heat exchanger

Related information

- Qingdao Ruipute successfully developed a new type of plate heat exchanger rubber gasket

- Comparative analysis of plate and shell heat exchanger and plate heat exchanger

- The custom manufacturer of lubricating oil plate heat exchanger chooses Qingdao RPT

- Installation, use and maintenance of plate heat exchanger

- Plate sterilizer supporting the use of plate heat exchanger and equipment requirements

- What are the advantages of plate heat exchangers compared to conventional heat exchangers?

Relevant article

- Heat station supporting plate heat exchanger installation is a technical work, these points should be noted

- Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what

- Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency

- A high-quality petrochemical plate heat exchanger in the production of what to consider

- These causes of chemical plate heat exchanger gasket aging you may not know

- Chemical plant plate heat exchanger, sulfuric acid cooling needs attention

- High-end plate heat exchanger customization, specifically for your special working conditions

- The working principle of gasket type industrial plate heat exchanger and the scenarios of its use are worth knowing in depth

- Still worrying about the wholesale price of industrial plate heat exchangers? An article to make you no longer tangled

- The original lubricant in the chemical plate heat exchanger plays so many roles!

Latest information

- Heat station supporting plate heat exchanger installation is a technical work, these points should be noted

- Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what

- Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency

- A high-quality petrochemical plate heat exchanger in the production of what to consider

- These causes of chemical plate heat exchanger gasket aging you may not know

- Chemical plant plate heat exchanger, sulfuric acid cooling needs attention

- High-end plate heat exchanger customization, specifically for your special working conditions

- The working principle of gasket type industrial plate heat exchanger and the scenarios of its use are worth knowing in depth

- Still worrying about the wholesale price of industrial plate heat exchangers? An article to make you no longer tangled

- The original lubricant in the chemical plate heat exchanger plays so many roles!