Application of plate and shell heat exchanger in boiler water supply

Nowadays, the advantages of heat exchangers are recognized by more and more customers. The use of plate and shell heat exchangers is becoming more and more extensive. Today, rupte takes everyone to understand the application of plate and shell heat exchangers in boiler water supply.

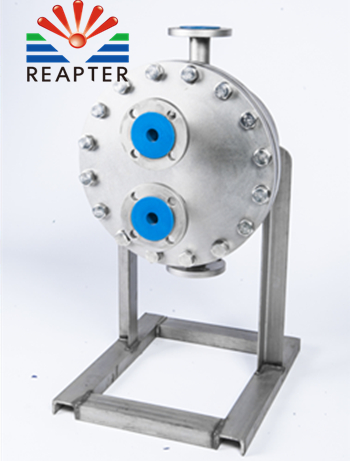

Plate and shell heat exchanger is a kind of structural form close to the middle of shell and tube heat exchanger and plate and shell heat exchanger. It has the advantages of both of them. With plate as the heat transfer surface, the heat transfer efficiency is good. The heat transfer coefficient is about twice of that of shell and tube heat exchanger. Compact structure and small size. It is resistant to high temperature and pressure. The maximum operating temperature is 800?and the maximum pressure is 6.3kpa. So what are the advantages of shell and plate heat exchanger in boiler water supply? 1. Energy saving and environmental protection. According to the indirect connection of plate and shell heat exchanger in heating, the operating system is more green and environmentally friendly than the direct connection heating system. 2. Boiler protection: if the boiler is used as the heat source, the boiler will be protected from the influence of scale and dirt. Since the water of the boiler is recycled independently after adding the heat exchanger, most of the water will not leak from the outside, so as to reasonably reduce the scale and dirt and increase the service life of the boiler. 3. Protection of heating pipes: plate and shell heat exchanger is used in central heating. First, if the pipe is floor heating pipe, it can be maintained according to the appropriate temperature of the heat exchanger when it is not resistant to high temperature. Second, it can get rid of the residue of central heating pipe, which is beneficial to protect the pipe and increase the service life.

Generally speaking, the function of shell and plate heat exchanger in boiler water supply is equal to improving a cycle of water supply and drainage, but it is more cost-effective than water pump, with low operating cost, reasonable saving of funds and improvement of work efficiency. Rept has many years of experience in heat exchanger production and processing, has a perfect high-tech elite team and the overall strength of independent R & D, production and processing. According to the development of the industry, we keep pace with the times. We have established a chemical laboratory to provide free testing services for customers, so as to ensure more accurate design concept, calculation and data information. If you have this demand, welcome to consult and visit.

Related information

- plate heat exchanger gasket causes problems, these factors are the key

- Reasons for the large price difference of GEA plate heat exchangers?

- Large professional plate and shell heat exchanger manufacturer-Qingdao Ruipute

- The small corrugation of the plate heat exchanger plate has such a big effect!

- What is the difference between the hanging holes on the plate heat exchanger plate? What's the effect on heat exchange?

- How to improve the heat transfer coefficient of heat exchanger

Relevant article

- Heat station supporting plate heat exchanger installation is a technical work, these points should be noted

- Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what

- Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency

- A high-quality petrochemical plate heat exchanger in the production of what to consider

- These causes of chemical plate heat exchanger gasket aging you may not know

- Chemical plant plate heat exchanger, sulfuric acid cooling needs attention

- High-end plate heat exchanger customization, specifically for your special working conditions

- The working principle of gasket type industrial plate heat exchanger and the scenarios of its use are worth knowing in depth

- Still worrying about the wholesale price of industrial plate heat exchangers? An article to make you no longer tangled

- The original lubricant in the chemical plate heat exchanger plays so many roles!

Latest information

- Heat station supporting plate heat exchanger installation is a technical work, these points should be noted

- Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what

- Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency

- A high-quality petrochemical plate heat exchanger in the production of what to consider

- These causes of chemical plate heat exchanger gasket aging you may not know

- Chemical plant plate heat exchanger, sulfuric acid cooling needs attention

- High-end plate heat exchanger customization, specifically for your special working conditions

- The working principle of gasket type industrial plate heat exchanger and the scenarios of its use are worth knowing in depth

- Still worrying about the wholesale price of industrial plate heat exchangers? An article to make you no longer tangled

- The original lubricant in the chemical plate heat exchanger plays so many roles!