Plate heat exchanger manufacturers reveal secrets for you

Gasket of the plate heat exchanger is an important part of the heat exchanger, which has an important impact on the service life of the plate heat exchanger. If these gaskets harden and lose their elasticity, it may lead to the failure of the heat exchanger. Therefore, the sealant strip is the most important and demanding accessory in plate heat exchanger. Here is a brief introduction of Qingdao ruipute plate heat exchanger rubber processing technology.

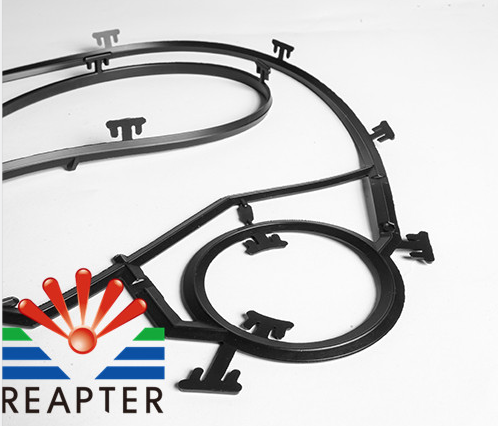

Qingdao ruipute plate heat exchanger gasket

Rubber is a relatively complex polymer system, which is usually composed of rubber polymer, vulcanizing agent, filler, antioxidant, processing aid and diluent. Although processing aid can not prolong the service life of rubber gasket, they can be used to improve, extrude and mold pressing performance in the manufacturing process of gasket. The selection and proportion of raw materials will determine the material of rubber gasket of plate heat exchanger. The final performance of the system. Among them, natural rubber is made from latex of Hevea brasiliensis, and its basic chemical composition is cis isoprene. Isoprene is a high CIS synthetic rubber made from isoprene. Because its structure and properties are similar to natural rubber, it is also called synthetic natural rubber. Styrene butadiene rubber is prepared by copolymerization of butadiene and styrene. According to the production method, it is divided into emulsion polymerized styrene butadiene rubber and solution polymerized styrene butadiene rubber. Cis-1,4-polybutadiene rubber is made by polymerization of butadiene. Compared with other general-purpose rubber, the vulcanized cis-1,4-polybutadiene rubber has better cold resistance, wear resistance and elasticity, less heat under dynamic load, good aging resistance, and is easy to be used together with natural rubber, chloroprene rubber, nitrile rubber, etc.

Generally, the manufacturing process the gasket plate heat exchanger of includes five steps

1. The mixing step of mixed rubber is to mix various raw materials and auxiliary materials according to the formula;

2. Forming a rubber material blank, that is, the rubber material is made into a rubber strip through an extruder device;

3. In the forming step, the vulcanized rubber strip is put into the die cavity of the hot die, the die is closed for vulcanization, and the rubber gasket is formed in the stamping equipment;

4. After vulcanization, the vulcanized gasket is statically placed in the oven to complete vulcanization;

5. Finished product inspection, that is, according to the process standard to take out some finished products for finished product inspection.

Qingdao ruipute heat exchange equipment manufacturing Co., Ltd., as a plate heat exchanger manufacturer, produces the gasket plate heat exchanger in strict accordance with American ASME standard and European CE standard. Its domestic business is mainly to replace imported plate heat exchangers and accessories for high-end customers. The company's quality level and technical service level have been widely praised by customers at home and abroad. Welcome customers to call to negotiate.

Related information

- How good is the coal chemical plate heat exchanger? Sealant gasket selection is the key

- The methods of plate heat exchanger anti-freezing

- The manufacturer who can perfectly replace alfa Laval double wall plate heat exchanger

- Can plate heat exchanger be directly used for feed water heating or cooling?

- Common methods for replacing plates and sealing gaskets in plate heat exchanger manufacturers

- Ruipute teaches you how to store plate heat exchangers such as alfa laval

Relevant article

- Heat station supporting plate heat exchanger installation is a technical work, these points should be noted

- Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what

- Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency

- A high-quality petrochemical plate heat exchanger in the production of what to consider

- These causes of chemical plate heat exchanger gasket aging you may not know

- Chemical plant plate heat exchanger, sulfuric acid cooling needs attention

- High-end plate heat exchanger customization, specifically for your special working conditions

- The working principle of gasket type industrial plate heat exchanger and the scenarios of its use are worth knowing in depth

- Still worrying about the wholesale price of industrial plate heat exchangers? An article to make you no longer tangled

- The original lubricant in the chemical plate heat exchanger plays so many roles!

Latest information

- Heat station supporting plate heat exchanger installation is a technical work, these points should be noted

- Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what

- Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency

- A high-quality petrochemical plate heat exchanger in the production of what to consider

- These causes of chemical plate heat exchanger gasket aging you may not know

- Chemical plant plate heat exchanger, sulfuric acid cooling needs attention

- High-end plate heat exchanger customization, specifically for your special working conditions

- The working principle of gasket type industrial plate heat exchanger and the scenarios of its use are worth knowing in depth

- Still worrying about the wholesale price of industrial plate heat exchangers? An article to make you no longer tangled

- The original lubricant in the chemical plate heat exchanger plays so many roles!