Ruipute's three most widely used heat exchangers in the petrochemical and natural gas industry

The three major heat transfer equipment widely used in the petrochemical and natural gas industry are plate heat exchanger, plate shell heat exchanger and semi-welded plate heat exchanger. The petrochemical and natural gas industry is the representative of China's basic industry, in which the liquid phase, vapor phase media changes and product heating, cooling, condensation, evaporation and other aspects, there are our three major heat transfer equipment.

One of the equipments for the petrochemical and natural gas industry in Qingdao Ruipute is the plate and shell heat exchanger. It consists mainly of external objects as well as internal plate packs. The plate pack is made up of corrugated metal sheets welded together in a circle according to the hole, and the circular plate pack has a more uniform stress distribution than the square plate pack. Liquid-liquid, gas-liquid, gas-gas and other heat transfer processes are widely used in the petrochemical and natural gas industry, and can be applied to heaters, evaporators, condensers, coolers, etc.

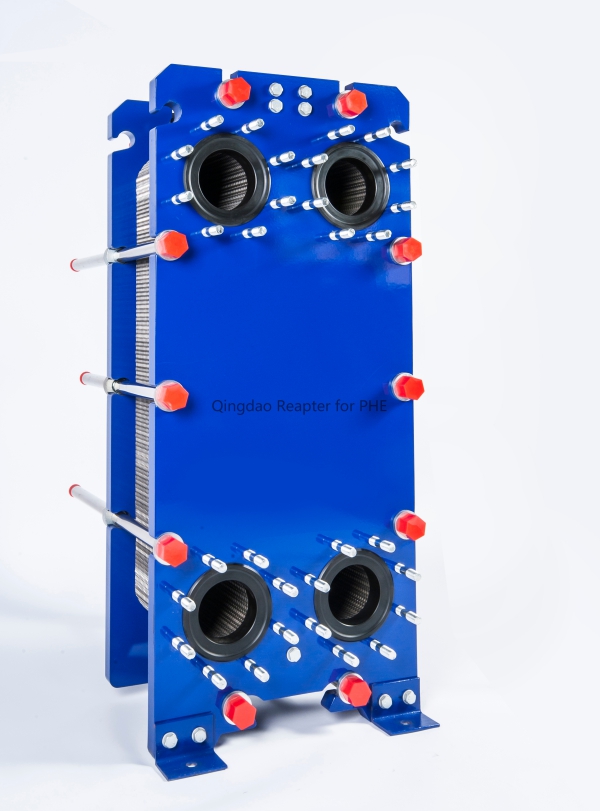

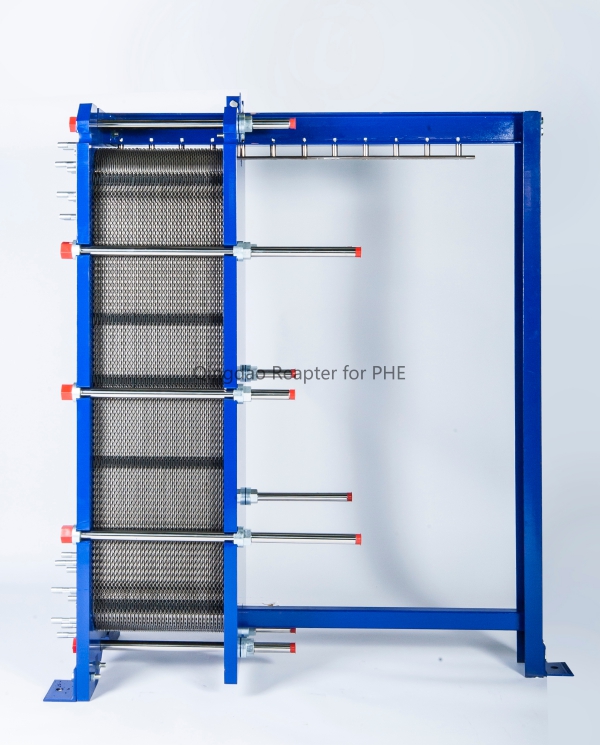

The second equipment in Qingdao Ruipute is the detachable plate type heat exchanger for the petrochemical and natural gas industry. Qingdao Ruiput can produce more than 200 kinds of plates, with different corrugations, depth, spacing, thickness and so on to meet the needs of a variety of working conditions. The use of special materials such as titanium, titanium palladium, hastelloy and other special materials can solve some of the corrosion problems and are widely used in the petrochemical industry. The use of professional selection software to ensure scientific selection and the use of precision machining presses ensure a high level of product quality.

Qingdao Ruipute petrochemical and natural gas industry application heat exchanger equipment of three:semi-welded plate heat exchanger. Its construction features two plates welded together to form a pair of plates, which are sealed with a sealant strip between the plates to form a separate flow channel. At present, it is more promising for the development of high temperature and high pressure media and corrosive petrochemical conditions, can be widely used. Safety has been greatly improved.

Qingdao Ruipute's three major heat exchangers are widely used in the petrochemical gas industry, proving the importance of energy saving and environmental protection in the petrochemical industry and the high quality of Ruipute's heat exchangers from the side.

Related information

- What are the applications of plate and shell heat exchanger in the field of petroleum refining

- What are the advantages of industrial plate heat exchangers in applications

- Feicheng sea crystal salinization using Ripple plate heat exchanger case

- High quality GEA plate heat exchanger plate and gasket replacement.

- The conditions for selecting a plate heat exchanger manufacturer are as follows

- Each manufacturer has different prices for plate heat exchangers, so what manufacturers are recommended

Relevant article

- 1

- Can plate heat exchanger be directly used for feed water heating or cooling?

- Why the heat transfer efficiency of plate heat exchangers in the heating industry is low

- How to determine the size and angle of plate heat exchanger plate?

- What is the proportion of pressure drop in the selection of plate heat exchanger?

- Why do we recommend food grade plate heat exchanger for beer brewing and fermentation? What should we pay attention to?

- What is the difference between the hanging holes on the plate of plate heat exchanger?

- What are the applications of plate and shell heat exchanger in the field of petroleum refining

- What is the key to the manufacture of plate heat exchangers with small temperature differences?

- How to descale the plate heat exchanger? What problems should be paid attention to during use?

Latest information

- Heat station supporting plate heat exchanger installation is a technical work, these points should be noted

- Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what

- Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency

- A high-quality petrochemical plate heat exchanger in the production of what to consider

- These causes of chemical plate heat exchanger gasket aging you may not know

- Chemical plant plate heat exchanger, sulfuric acid cooling needs attention

- High-end plate heat exchanger customization, specifically for your special working conditions

- The working principle of gasket type industrial plate heat exchanger and the scenarios of its use are worth knowing in depth

- Still worrying about the wholesale price of industrial plate heat exchangers? An article to make you no longer tangled

- The original lubricant in the chemical plate heat exchanger plays so many roles!