How to descale the plate heat exchanger? What problems should be paid attention to during use?

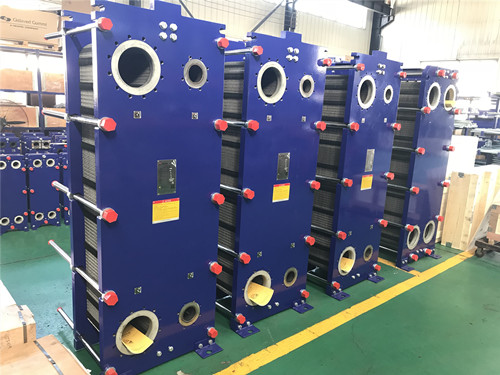

With the development of industry, plate heat exchangers have gradually become popularized and generalized with their own advantages, especially in terms of water-to-water heat exchange. As the heat exchanger works, after a long period of time, it will often cause scale deposition.

As a result, the heat exchange efficiency is reduced, so we need to disassemble and descaling the plates.

So how to descale the plates?

The first is to disassemble the heat exchanger first. The heat exchanger can be disassembled in a stable and open place according to the site conditions. The tightening size of the heat exchanger needs to be measured with a tape before the disassembly, and recorded for backup.

Use a wrench to loosen the heat exchanger screws according to the diagonal principle, and then remove the tightening screws, and then push the movable compression plate to the side of the column, lift the plate from the back, and tilt the plate back and forth to take out the plate.

Keeping the plates clean is one of the important conditions for maintaining the efficient heat transfer coefficient of the plate heat exchanger. The medium between the plates moves along the narrow and tortuous passages. Even if the scale is not too thick, it is enough to cause the larger

The change significantly affects the flow of the fluid, causing the pressure drop to increase and the heat transfer coefficient to decrease. Generally speaking, chemical cleaning or physical cleaning is mainly used for scale removal, that is, for general scale layers, chemical cleaning is sufficient, but for

For thicker scales, the plates need to be chemically softened first, and after softening, the scales should be removed mechanically (physically) to ensure the clean surface of the plates.

After cleaning, the heat exchanger needs to be restored and installed. In the process of plate installation, ensure that the plate installation position is correct, the plate size and angle distribution is correct, and the plate angle direction is correct. It is best to remove it

Record these characteristics from time to time, otherwise it will cause the heat exchanger to leak or decrease the heat exchange capacity after installation.

After the plates are arranged, the heat exchanger needs to be tightened. The tightening method uses a screw to tighten, and the tightening is required to be even, and the tightening size of the plates is restored to the tightening size before disassembly.

Loose, too tight will cause deformation of the plate, too loose will cause leakage of the heat exchanger.

After the heat exchanger is assembled, a pressure test is required. If there is no problem with the pressure test and pressure maintaining, it can be determined that the heat exchanger is installed correctly and can be used normally.

The general test pressure is 1.3 times the design pressure.

The assembly of the heat exchanger is an important step in the descaling process. If there is a defect in the second step, it needs to be disassembled and assembled again, which is time-consuming and laborious.

Qingdao Ripter specializes in the production and design of heat exchangers. Naturally, it is no longer necessary to clean up and descaling heat exchangers, and the production of heat exchangers is customized to meet your various requirements.

As a result, the heat exchange efficiency is reduced, so we need to disassemble and descaling the plates.

So how to descale the plates?

The first is to disassemble the heat exchanger first. The heat exchanger can be disassembled in a stable and open place according to the site conditions. The tightening size of the heat exchanger needs to be measured with a tape before the disassembly, and recorded for backup.

Use a wrench to loosen the heat exchanger screws according to the diagonal principle, and then remove the tightening screws, and then push the movable compression plate to the side of the column, lift the plate from the back, and tilt the plate back and forth to take out the plate.

Keeping the plates clean is one of the important conditions for maintaining the efficient heat transfer coefficient of the plate heat exchanger. The medium between the plates moves along the narrow and tortuous passages. Even if the scale is not too thick, it is enough to cause the larger

The change significantly affects the flow of the fluid, causing the pressure drop to increase and the heat transfer coefficient to decrease. Generally speaking, chemical cleaning or physical cleaning is mainly used for scale removal, that is, for general scale layers, chemical cleaning is sufficient, but for

For thicker scales, the plates need to be chemically softened first, and after softening, the scales should be removed mechanically (physically) to ensure the clean surface of the plates.

After cleaning, the heat exchanger needs to be restored and installed. In the process of plate installation, ensure that the plate installation position is correct, the plate size and angle distribution is correct, and the plate angle direction is correct. It is best to remove it

Record these characteristics from time to time, otherwise it will cause the heat exchanger to leak or decrease the heat exchange capacity after installation.

After the plates are arranged, the heat exchanger needs to be tightened. The tightening method uses a screw to tighten, and the tightening is required to be even, and the tightening size of the plates is restored to the tightening size before disassembly.

Loose, too tight will cause deformation of the plate, too loose will cause leakage of the heat exchanger.

After the heat exchanger is assembled, a pressure test is required. If there is no problem with the pressure test and pressure maintaining, it can be determined that the heat exchanger is installed correctly and can be used normally.

The general test pressure is 1.3 times the design pressure.

The assembly of the heat exchanger is an important step in the descaling process. If there is a defect in the second step, it needs to be disassembled and assembled again, which is time-consuming and laborious.

Qingdao Ripter specializes in the production and design of heat exchangers. Naturally, it is no longer necessary to clean up and descaling heat exchangers, and the production of heat exchangers is customized to meet your various requirements.

【Paper label】:plate heat exchanger

Related information

- How to find a wide channel plate heat exchanger as GEA quality?

- The performance of imported liquid plate heat exchanger from these three aspects is correct

- All that you want to know about GEA NT Series plate heat exchanger is here

- The methods of plate heat exchanger anti-freezing

- What are the advantages of industrial plate heat exchangers in applications

- Experienced technical workers tell you: how to detect the plate heat exchanger gasket:

Relevant article

- 1

- Can plate heat exchanger be directly used for feed water heating or cooling?

- Why the heat transfer efficiency of plate heat exchangers in the heating industry is low

- How to determine the size and angle of plate heat exchanger plate?

- What is the proportion of pressure drop in the selection of plate heat exchanger?

- Why do we recommend food grade plate heat exchanger for beer brewing and fermentation? What should we pay attention to?

- What is the difference between the hanging holes on the plate of plate heat exchanger?

- What are the applications of plate and shell heat exchanger in the field of petroleum refining

- What is the key to the manufacture of plate heat exchangers with small temperature differences?

- How to descale the plate heat exchanger? What problems should be paid attention to during use?

Latest information

- Heat station supporting plate heat exchanger installation is a technical work, these points should be noted

- Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what

- Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency

- A high-quality petrochemical plate heat exchanger in the production of what to consider

- These causes of chemical plate heat exchanger gasket aging you may not know

- Chemical plant plate heat exchanger, sulfuric acid cooling needs attention

- High-end plate heat exchanger customization, specifically for your special working conditions

- The working principle of gasket type industrial plate heat exchanger and the scenarios of its use are worth knowing in depth

- Still worrying about the wholesale price of industrial plate heat exchangers? An article to make you no longer tangled

- The original lubricant in the chemical plate heat exchanger plays so many roles!