Plate configurations in single and multi-process plate heat exchangers

The plate heat exchanger has many applications, and the specific working conditions determine its process configuration, mainly single-process and multi-process configuration, the specific use of which configuration to be determined according to the actual working conditions, then single-process and multi-process design of the plate configuration of what exquisite?

The application scope of plate heat exchangers can be divided into several categories, mainly the HVACR industry, petrochemical and natural gas industry, beer and beverage industry, paper industry, pharmaceutical industry, power generation industry, each industry on the use of plate exchange are not the same, is said to be the single process and multi-process.

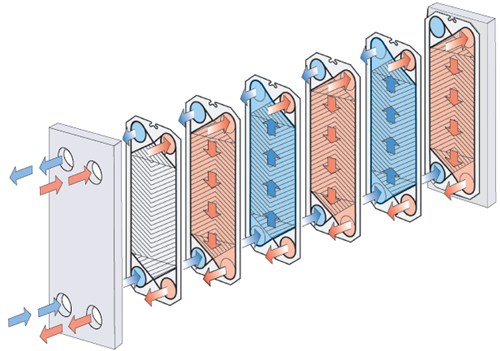

Plate heat exchanger by a group of corrugated metal plate composition, are equipped with interface holes for the two sides of the temperature difference between the inflow and outflow of fluid. Heat transfer takes place between the two media through the heat transfer plate plates. The set of plates is assembled between the fixed clamping plate and the movable clamping plate and is pressed down by fastening bolts. The plates are equipped with sealing gaskets, which seal the inter-plate channels and allow fluid to flow into the adjacent channels. The plate ripples cause turbulence and support the plates against differential pressure.

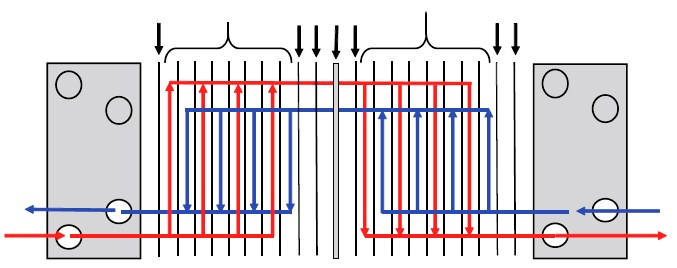

There are only two plates in a single-flow configuration that do not transfer heat, the head and tail plates. The single flow has a blind plate attached at the end, which is a plate with four corner holes sealed to prevent contact between the medium and the clamping plate.

Multi-flow configurations can be created through the use of steering plates without perforated ports. This is primarily to change the direction of flow of one or both fluids. Multi-flow can be used for processes where the media requires slower heating resulting in longer heating times. Four ports are formulated on either side. For example, in a two-flow configuration, there are three plate plates that do not transfer heat.

The plate heat exchanger single and multi-process configurations are achieved using a combination of plates designed to use different conditions to reduce costs as much as possible.

Related information

- Where is the wide gap better than the tube type heat exchanger?

- Count the reasons for the leakage of the gasket of the plate heat exchanger, and use the product well under the harsh working conditions

- Professional teacher for you to reveal the secret plate heat exchanger heating shortage when the solution

- Analysis of problems with heat transfer efficiency and pressure drop in plate and shell heat exchangers

- Why your plate heat exchanger gasket swelling happens?

- What is the difference between the corrugated herringbone and the horizontal corrugation on the plate heat exchanger

Relevant article

- 1

- Can plate heat exchanger be directly used for feed water heating or cooling?

- Why the heat transfer efficiency of plate heat exchangers in the heating industry is low

- How to determine the size and angle of plate heat exchanger plate?

- What is the proportion of pressure drop in the selection of plate heat exchanger?

- Why do we recommend food grade plate heat exchanger for beer brewing and fermentation? What should we pay attention to?

- What is the difference between the hanging holes on the plate of plate heat exchanger?

- What are the applications of plate and shell heat exchanger in the field of petroleum refining

- What is the key to the manufacture of plate heat exchangers with small temperature differences?

- How to descale the plate heat exchanger? What problems should be paid attention to during use?

Latest information

- Heat station supporting plate heat exchanger installation is a technical work, these points should be noted

- Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what

- Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency

- A high-quality petrochemical plate heat exchanger in the production of what to consider

- These causes of chemical plate heat exchanger gasket aging you may not know

- Chemical plant plate heat exchanger, sulfuric acid cooling needs attention

- High-end plate heat exchanger customization, specifically for your special working conditions

- The working principle of gasket type industrial plate heat exchanger and the scenarios of its use are worth knowing in depth

- Still worrying about the wholesale price of industrial plate heat exchangers? An article to make you no longer tangled

- The original lubricant in the chemical plate heat exchanger plays so many roles!