Edible oil plate shell heat exchanger, has relation with instant noodles unexpectedly?

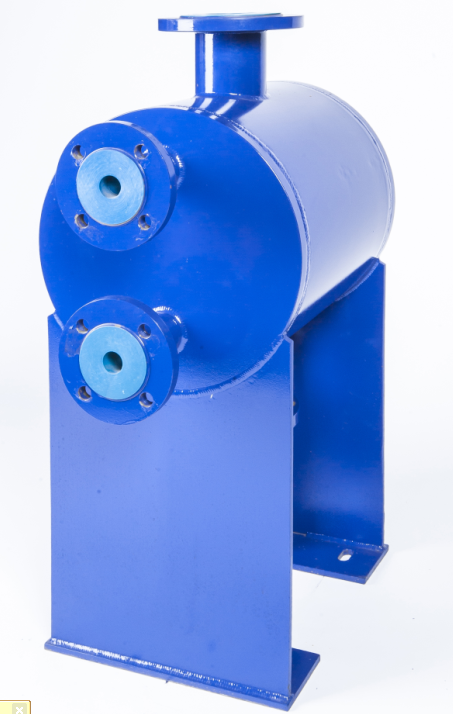

Edible oil plate-shell heat exchanger is a commonly used equipment under the condition of heat exchange of edible oil or constant temperature.Of course, but all involved in the cooking oil application of the working conditions, must be inseparable from its figure.The production of instant noodles is one of the more common applications, and many people wonder how it can be related to this?The answer is yes.

There are many processes in the production of instant noodles, including making noodles, curing, calendering, cutting strips, steaming, cutting off, frying, air-cooling and drying, and finally packaging.In this case, the plate and shell heat exchanger is used in the frying condition.Because the oil temperature is too high or too low will have an impact on instant noodles, because to maintain a constant temperature, such as 140-150 degrees is more appropriate, of course, the oil temperature is too low Fried not ripe, oil temperature is too high easy to coke.

Therefore, controlling oil temperature is a key factor.Another factor is that at such high temperatures, the rubber strip cannot be used, so the advantages of removing the gasket have become apparent.Corrugated sheets are conducive to the formation of turbulence and the enhancement of heat exchange efficiency.

The application of edible oil plate-shell heat exchanger on convenience surface is just a microcosm of food application. It is also widely used in palm oil and other aspects. If you are interested in this kind of equipment, please contact us.

Related information

- The advantages of Qingdao Reapter plate and shell heat exchanger that you should know:

- Food grade plate heat exchanger—Qingdao Ruipute

- China plate and shell heat exchanger manufacturers product advantage reflects

- Hastelloy plate shell heat exchanger sulfuric acid and other bad working conditions, compared with stainless steel what is the advantage

- Does semi welded plate heat exchanger real expensive?

- Qingdao Ruipute wide flow channel plate heat exchanger processing customization

Relevant article

- 1

- Can plate heat exchanger be directly used for feed water heating or cooling?

- Why the heat transfer efficiency of plate heat exchangers in the heating industry is low

- How to determine the size and angle of plate heat exchanger plate?

- What is the proportion of pressure drop in the selection of plate heat exchanger?

- Why do we recommend food grade plate heat exchanger for beer brewing and fermentation? What should we pay attention to?

- What is the difference between the hanging holes on the plate of plate heat exchanger?

- What are the applications of plate and shell heat exchanger in the field of petroleum refining

- What is the key to the manufacture of plate heat exchangers with small temperature differences?

- How to descale the plate heat exchanger? What problems should be paid attention to during use?

Latest information

- Heat station supporting plate heat exchanger installation is a technical work, these points should be noted

- Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what

- Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency

- A high-quality petrochemical plate heat exchanger in the production of what to consider

- These causes of chemical plate heat exchanger gasket aging you may not know

- Chemical plant plate heat exchanger, sulfuric acid cooling needs attention

- High-end plate heat exchanger customization, specifically for your special working conditions

- The working principle of gasket type industrial plate heat exchanger and the scenarios of its use are worth knowing in depth

- Still worrying about the wholesale price of industrial plate heat exchangers? An article to make you no longer tangled

- The original lubricant in the chemical plate heat exchanger plays so many roles!